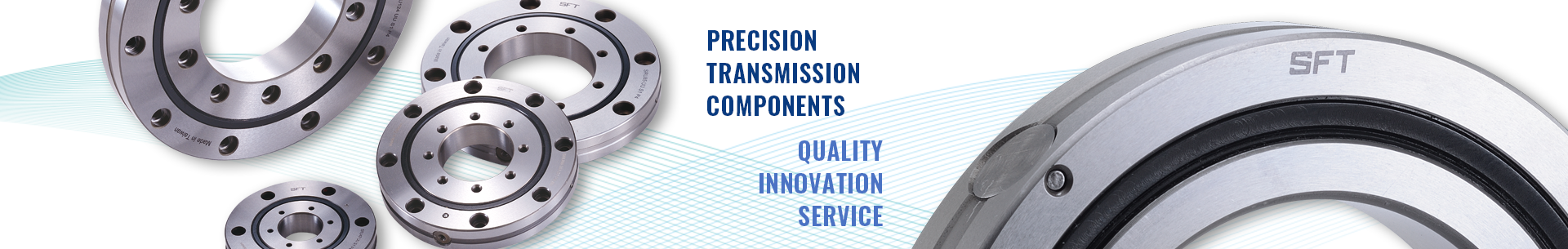

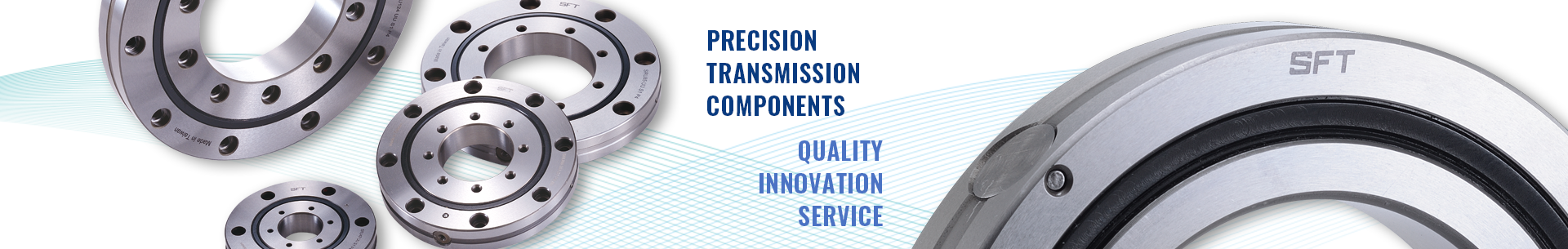

Crossed roller bearings are a type of roller bearing characterized by cylindrical rollers arranged in a crossed pattern between inner and outer raceways.This design allows the bearing to accommodate loads from multiple directions, including radial, axial, and moment loads. Crossed roller bearings are commonly used in applications requiring high precision and high rigidity, such as machine tools, robotics, and measurement equipment. They feature compact dimensions, high load-carrying capacity, and maintain high precision and smooth operation.

1.High rigidity:

Crossed roller bearings have a unique structure that enables them to provide high rigidity in all directions, making them suitable for applications with heavy loads and high precision requirements.

2.High load capacity:

Despite their compact size, crossed roller bearings can withstand high radial, axial, and moment loads, making them suitable for heavy-duty applications. Minimal elastic deformation: The crossed roller design minimizes elastic deformation under load, ensuring stable performance and accurate positioning over time. Compact design: Crossed roller bearings have a compact structure, allowing for space-saving designs in various applications.

3.High rotational accuracy:

Due to their design, crossed roller bearings offer excellent rotational accuracy, making them ideal for applications where precise positioning is critical, such as machine tools and robotics.

4.Compactness:

With their rollers arranged in a crossed pattern, these bearings provide low friction and smooth operation, reducing energy consumption and extending service life.

5.Easy installation and maintenance:

Crossed roller bearings are designed for easy installation and maintenance, contributing to overall system efficiency and uptime.

Due to the thin wall structure of the cross roller bearings, full consideration must be given to the rigidity of the housing and flange discs. With split type bearings, if the housing or flange disc is not rigid enough, the inner ring or outer ring cannot be evenly held, resulting bearing deformation when moment load is applied. Therefore, the contact area of the rollers will become uneven, causing significant decrease in bearing performance.

How to fix the flange and locking screws when using crossed roller bearings, ensure the following:

1.Flange mounting: The flange should be securely mounted to the housing to prevent any movement during operation. It's important to align the flange properly with the bearing to maintain accuracy and prevent excessive load on the bearing.

2.Locking screws: Use appropriate locking screws to secure the bearing in place. Ensure that the screws are tightened evenly and to the recommended torque to prevent distortion of the bearing and ensure proper alignment.

3.Avoid over-tightening: Over-tightening the screws can lead to bearing damage or misalignment. Follow the manufacturer's guidelines for tightening torque to avoid such issues.

4.Check for smooth rotation: After mounting the flange and tightening the screws, check that the bearing can rotate smoothly without any resistance. If there is any stiffness or resistance, double-check the alignment and screw tightness.

By following these steps, you can effectively fix the flange and locking screws when using crossed roller bearings, ensuring smooth operation and longevity of the bearing. You may also refer to page11 from SFT cross roller bearing catalog .

Prepare the shaft and housing: Ensure that the shaft and housing are clean and free from any debris or contaminants. Check for any burrs or irregularities that could affect the installation.

Mount the bearing: Slide the crossed roller bearing onto the shaft or into the housing, ensuring proper alignment with the mating surfaces. Pay attention to any alignment marks or indicators provided by the manufacturer.

Secure the bearing: Use appropriate mounting bolts or screws to secure the bearing in place. Tighten them evenly and to the recommended torque to avoid distortion of the bearing.

Check for smooth rotation: After mounting the bearing, check that it can rotate smoothly without any resistance. If there is any stiffness or resistance, double-check the alignment and screw tightness.

Install additional components: If necessary, install any additional components such as seals, covers, or retaining rings according to the manufacturer's instructions.

Lubricate: Apply lubrication as per the manufacturer's recommendations to ensure smooth operation and longevity of the bearing.

By following these steps, you can properly install crossed roller bearings for optimal performance in your application.